What gives you the power to make a stoppie at over 250 Km/h

A stoppie is a common thing for a stunt biker. But what about the MotoGP riders coming down a straight at over 250 Km/h with the rear wheel up in the air? That’s something spectacular! The series sports bikes these days are close to the MotoGP stopping performance, but where do they get it from?

Radial Calliper

The radial callipers were first introduced back in 1998 by Brembo. Since then, every sports bike features this kind of calilipers. The difference is rather small and consist in the mounting manner and feel. The axial calliper comes fitted with bolts parallel to the front wheel axle while the radial has the bolts mounted perpendicular to the axle like in the left photo.

The radial calliper comes with reduced lateral force which translates into reduced vibrations from the front end. These sensations and feedback are rather dedicated for race pilots than everyday riders, but we are glad these improvements are now on the series models.

Radial brake pump

The brake pump is definitely a game changer if you search for stopping accuracy. The common bikes feature axial brake pump, axial because the brake cylinder works parallel with the handlebar. The radial master cylinder gives you a more precise adjustment range in order to get the right feel.

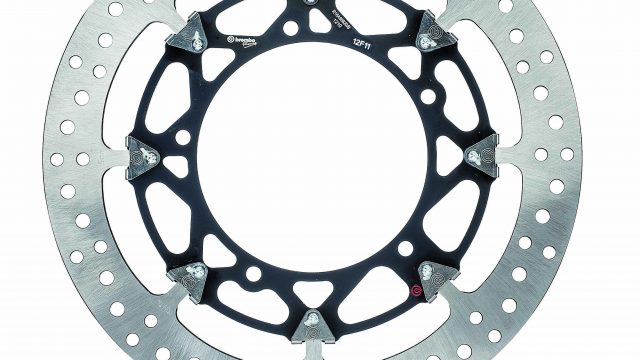

Floating disc

The original steel discs were good, actually very good, but you should ask yourself this question after you’ve experienced the latest racing brake rotors. The floating discs are the ultimate choice because they spread the heat and prevent the disc from warping. For example, a track bike that experiments hard braking for more than five times on a lap will heat up very hard. The solution that revolutionised MotoGP was also from Brembo, the T-Drive brake rotors. These discs feature increased thermal resistance, a full floating action and the carriers are CNC machined from aluminium to reduce the rotational mass. Until the release of carbon discs for MotoGP, the T-Drive was the best money could buy.

Braided steel lines

The braided steel lines are a must if we are talking about performance bikes. Their job is to transfer the hydraulic force from the brake pump to the calliper. To do this, the brake lines have to endure high temperatures and to resist the corrosion caused by brake fluid. The steel lines offer higher performance because of the ability to handle fluid at temperatures over 200 degrees Celsius.

Brake pads

The brake pads have the hardest job in the stopping system. They have to stand against the extreme conditions and to be able to perform till the last lap. The pads are built out of specially designed materials to ensure superior braking power and good control. The pads manufacturers provide superior solutions for every riding segment, from ceramic to sintered – you only have to pick the ones that fit you.